Word count: 2959. Estimated reading time: 14 minutes.

- Summary:

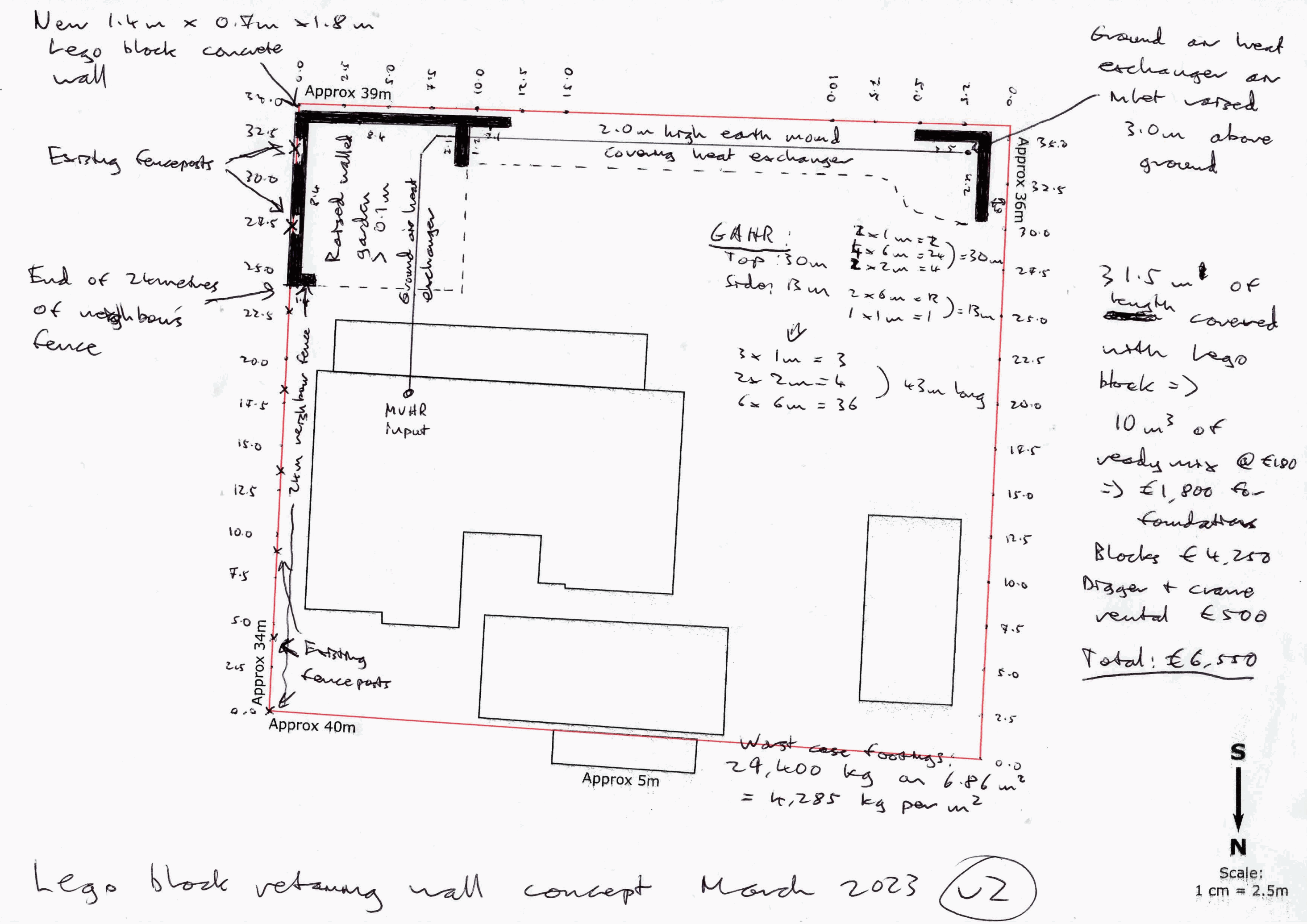

- The Ground Air Heat Exchanger (GARE) installation plan looks like this: A top-down view doesn’t convey everything going on there: the GAHE enters the house via an underground pipe, and condensate from warm humid air meeting cooler earth drips downwards. The pipes are made by Rehau, a Swiss polymers manufacturer, and need to be installed this summer for optimal performance.

Sunday 26 March 2023: 22:35.

- Summary:

- The Ground Air Heat Exchanger (GARE) installation plan looks like this: A top-down view doesn’t convey everything going on there: the GAHE enters the house via an underground pipe, and condensate from warm humid air meeting cooler earth drips downwards. The pipes are made by Rehau, a Swiss polymers manufacturer, and need to be installed this summer for optimal performance.

The Ground Air Heat Exchanger (the ‘GARE’)

The GARE is simply 40 metres of dumb 200 mm diameter plastic pipe buried in the ground. The idea is that the house MVHR air inlet draws fresh air through the GAHE before it enters the house, so fresh air is brought closer in temperature to several metres underground i.e. cooler in summer, and warmer in winter. The heat exchange efficiency of modern MVHRs is so good that the GARE makes very little difference in winter, so its main purpose is to provide cooling for the house in summer. My probably not very accurate maths reckon it should be worth about 1kW of cooling, which for a normal Irish house wouldn’t be worth much. However, for a Passive House we have much much better air tightness, so that 1kW of cooling goes much further.

GAREs are rarely installed in the UK or Ireland, and mainly for commercial. It is nearly unheard of to install them for a domestic building in this part of the world, despite their being popular enough elsewhere in Europe and north of Africa. This is because only around 15% of the land in Britain and Ireland is suitable due to the wrong soil type or wrong internal pressure, plus you need to have the right kind of site as well. I specifically chose my site as I reckoned it ought to be unusually suitable for a GARE.

The installation plan looks like this:

A top down view doesn’t convey everything going on there: the GAHE enters the house via an underground 315 mm diameter pipe 2.5m long standing vertically on its end underneath the house. Until the GAHE 200 mm pipe reaches this vertical pipe, it slopes downwards during its entire length, so condensate from warm humid air meeting cooler earth drips downwards. When the vertical 315 mm pipe is reached, the condensate pools at the bottom where a level activated pump removes it so it doesn’t induce mould.

About half of GAHEs fail within their first decade due to mould buildup caused by pooling of condensate along the pipe. This is mainly caused by incorrect installation, but also due to heavy construction vehicles putting pressure above which puts unanticipated kinks into the pipe. To prevent that happening here, as you can see I have taken the pipe immediately away from the building rather than looping it around the building’s foundations as would be more typical. We bring it up next to the drainage ditch, and run it the full length of that ditch. The idea is that the static pressure of rainfall upon the estate will cause a constant underground flow of water towards the ditch, thus refreshing the heat capacity of the soil surrounding the pipe. This is what I meant about needing the site to be right, the site is within a river basin and so has silty soil which has high thermal capacity, and we also have static pressure driving underground water flow underneath the site. Most sites in the UK and Ireland do not have both prerequisites for a GARE to work well.

The top of the 200 mm pipe enters the 315 mm pipe 1.8 meters below the house. Most GARE installations use a 1% slope, we however shall be using a 3% slope from the house to the ditch to prevent later kinks introducing condensate pooling. The brings the top of the pipe to 1.4m below the ground which is too high, so to account for that as you can see in the diagram we create a retained wall raised garden to increase the depth. It must be raised no less than 0.1 metres to keep the top of the GARE its minimum 1.5m below ground (and in reality, we’ll probably raise it 0.3-0.5 metres with well manured soil).

After the GARE turns right, its slope increases to 4% under the current plans. This raises it by 1.2 metres by the time it reaches the western air inlet. At this point its top is only 0.2 metres below ground, however we have all along the rear a 2.0 metre high earthen wall which is at least 3.0 metres thick at its base. This ensures that the pipe is never closer to the air than 1.5 metres right up to the inlet, which should maximise heat transfer. The quite steep 4% slope is to prevent kinks from dumping a 2.0 metre high packed earth wall on top of the pipe, it’s a lot of weight and more importantly, it’s permanent so the ground under the pipe will never get the opportunity to spring back.

If I do say so myself, this use for the excess soil on the site after the foundations are dug out is quite clever. There is an existing low earthern wall plus an old spill pile from somebody else’s house. Adding that with the expected soil removal for my house should fill that wall and leave about 20 m3 remaining. I plan to turn that into my ‘holy pool’ water feature some day in the far future when I get both free time and sufficient money to do it. Disposing of the soil costs about €70 per tonne/€140 per cubic metre, so it also saves me money if I make use of the excess soil instead of spending more money to have it taken away.

As great as all this may look, I have a big problem: the GARE pipes are made by Rehau who are a Swiss polymers manufacturer. And as I mentioned earlier, almost nobody in Ireland nor the UK uses these, so getting them delivered to Ireland is going to be a real pain. I got a quote from their Irish exclusive reseller for over €7k ex VAT delivered. I can get the same pipes in Germany from an online shop for under €4k ex VAT delivered to Germany and its neighbouring countries. There surely must be a way of getting them from there to here for under €3k, even surely me driving a van there via ferry and back would be cheaper than €3k.

The longest pipes are 6 metre lengths which is problematic for pallet based freight, which maxes out at the 2.4m pallet. I could drop to 3 metre or 1 metre lengths, but that very substantially increases the cost per metre from €56 to €84. I guess I can try my luck on https://www.shiply.com/ or equivalents assuming that the German online shop is willing, it’s a light load at under 300 kg, just awkward that’s all.

The shed

Back last summer when I was ordering a garden wagon with extra large wheels to save me ever again moving concrete blocks one at a time by hand, I was looking on the vendor’s site for other things to buy for the fairly large delivery cost and I decided to also purchase one of their steel garden sheds. I originally intended to put it at the front, but then I realised that duplicated functionality already provided by the shipping container, so I then decided to put it at the back. However lots of other things were higher priority, so whilst I bought it in September 2022, I only got round to erecting it this month.

I spent a fair bit of time umming and awing on this one. If you want a quality steel shed, it is extremely hard to beat Britain’s Asgard who manufacture sheds. For the spec, I know of nothing remotely close in price – take their 7 x 7 ft model for about €2,000 inc VAT, it has 1.2 mm thick steel sheet walls and roof, comes with a built in metal floor (note this is rare in sheds!), and weighs 326 kg so it doesn’t even need anchoring to the ground for hurricanes. It would require a bit of effort to break into, more than a sledgehammer or screwdriver, an angle grinder would do it.

With hindsight, I probably should have got one of those, however what I got instead is a 225 x 225 cm (7.5 x 7.5 ft) pent shed from Sheds Direct Ireland for €754 inc VAT. In contrast to the quality permeating the Asgard shed above, this one has claimed 0.3 mm (I suspect actually 0.25 mm, see below) walls and roof with a 0.6 mm structural frame. It is screwed together by around four hundred screws, with all the screws easily accessible on the outside so anybody with a screwdriver can get inside. I found the OEM product listing at https://www.sunor.cn/product/Skylight-Metal-Shed/, with their Alibaba listing showing the cost for more than two hundred per order as US$140 each (which excludes shipping to Ireland and taxes), and also the weight as 68 kg per item.

Which is about one fifth the weight of the Asgard shed above (note that 1.2 mm divided by five is 0.24 mm, which is why I think the vendor’s claim of 0.3 mm thick panels unlikely), yet still two fifths the price once including the added costs: (i) I needed a heavy and raised base to keep the shed off the ground and away from rising damp plus to anchor it against hurricanes, which cost me €70 inc VAT for thirty-six solid concrete blocks (ii) I needed to level those blocks into a flat surface which cost a few dozen kg of sand (iii) €120 inc VAT for thirty concrete tiles to create a hard wearing floor, though arguably I’d have had to fit the same to the Asgard shed (iv) I had to buy a new long shackle lock costing €35 for it because its stupid door handles are too far apart for any of my existing padlocks (v) and finally, and perhaps the most important, is my very scarce and precious free time of which this Chinese shed consumed around three full days! Admittedly, this was spread out over many days these past two weeks, however I reckon about twenty-five hours went into prepping and constructing this thing. Which is very far from the claimed ‘two to three hours’ by its vendor …

As you might be gathering, there is a touch of buyer’s remorse here. I remember at the time of purchase I was very much thinking ‘either go quality or go cheap’ and I don’t particularly rate the 0.5 mm thick panels most of the ‘premium’ metal shed vendors in Ireland use. Sure, 0.5 mm is a world better than 0.25 mm panels, but do you know what’s world’s better again? > 1.0 mm panels. They actually have a good bit of solidity to them – not as good as the 2.0 mm panels on a shipping container for sure, but they don’t feel quite so ‘tinny’ any more. Whereas 0.5 mm panels definitely feel tinny – indeed, when I bought the one metal box roof panel for the western wall, I opted for the 0.7 mm panel for a little added cost rather than the 0.5 mm panel which most go for. That extra heft I certainly noticed lifting the damn thing, but I’m also very confident it will never rust through before I am dead, and therefore I will never ever have to redo that roof before I die. When you tap it, the panel ‘rings’ like a bell, which isn’t tinny.

My new garden shed wasn’t intended to live so long – in fact, I expected it to be scrapped well before I die as it’s in the way of my planned future reed bed system, and after the outhouse gets built that’ll be my next major expense work item. So I didn’t want to spend too much, and I guess one fifth the shed for half the price of the Asgard shed is the tradeoff you make.

All that said, Zhejiang Long Yard Industry & Trade make an above average product, relative to others I have experienced. Most of the steel sheet edges are folded back to prevent cutting your hands during handling, and I didn’t get cut once, so they did well there. The predrilled holes mostly lined up, which is better than average. In about four places the holes didn’t quite line up, causing some of the metal panels to bunch slightly which will let in a small amount of rain if there were a storm. There were only two places with completely missing predrilled holes, and those were easily drilled in by my own hand. They chose polycarbonate rather than cheaper and much inferior acrylic for the window. The instructions weren’t great – I’d look at them more as inspiration for writing your own instructions – but I’ve also seen far, far worse, and the numbers on the parts did match those in the instructions for the most part, except when they didn’t, none of which was a showstopper. One thing annoying about the instructions is the ordering of what to do in sequence, the design is actually better than the instructions give it credit e.g. they have a mini roof panel just big enough for your head to stick up through so you can easily screw in all the big roof panels without needing to hang over the roof from a ladder, yet the instructions completely ignored that quite nice design feature. There were sufficient quantities of screws, washers, bolts etc and then some, as it is good to have spares. As much as I’ve lambasted the thin steel sheet, it does have the one huge advantage of single handed ease of assembly because you can feasibly hold a whole sheet in an awkward position with one hand as you screw it in with the other hand. Good luck achieving that with 1.2 mm thick sheet, where assembly really does need two people start to finish.

I will admit it looks quite smart with its two tone paint job:

And, ultimately, once assembled it is sturdy enough and weatherproof enough to have solved what I bought it for. It’ll do. I can’t say I had any love for the quantity of time it consumed, the head scratching over what the instructions meant, or having at times to ignore the instructions because bits didn’t line up so I was going to have to think laterally. I’d have preferred an easier time of it, to be honest, given I had spent a grand overall on it. Still, it’s done now – well, actually, it isn’t quite done yet, I haven’t anchored it to the floor nor installed its floor concrete tiles, which you can see stacked there in front. Maybe by the end of this week!

House build spend

I undoubtedly overspent last year. In fact, due to bad record keeping by me we actually spent €10k over what we could afford, whoopsie. Which led to an unpleasant cash crunch after Christmas due to end of year taxes going out, and I didn’t quite have enough money.

Anyway, all that’s behind us now. My last update on this went up to 1st January 2023, and this will be up to 1st April 2023:

- Spent: €184,672

- Committed to be spent soon: €4,329

- Current three month averaged spend rate: €6,736 per month

The four biggest ticket items in the past three months were: (i) Lithium batteries (ii) 60.5 m2 of concrete ‘lego’ bricks (iii) Three phase solar hybrid inverter (iv) Concrete blocks and concrete tiles for shed.

I’ll almost certainly write a separate post about those concrete ‘lego’ blocks, which let you build a cheap earth retaining wall, so I’ll say no more about those for now.

Fairly obviously the big blow out spend these past three months were the inverter and batteries which I originally ordered last summer, and they finally turned up some eight months later. Those unlock me getting mains electricity activated on the site, which I have set in motion. That will cost me at least five grand, unfortunately the bank will require that a mains electricity connection be activated during the build, so you don’t get much choice (you may remember I did some calculations, and I reckoned it actually cheaper to buy and run a diesel generator even assuming they will need regular replacement than get a mains electricity connection installed and then pay its annual standing charge and running costs).

The second large upcoming cost will be purchasing those GARE pipes mentioned above, which needs to happen soon if I want them installed this summer as they have a three month lead time. Past those two big ticket items, I don’t expect any further large expenses in the next three months at the current time. If the AIB set achievable terms for any mortgage they offer, that might change quickly – I’ll need to bring on a structural engineer and a M&E engineer and each will cost at least 10k. And from June onwards, I would need to shell out a whole ton load of cash for any prepatory groundworks to install the GARE etc, which is a blocker for the builders commencing build. I suspect that would more than wipe me out for this year, I’ll need to wait to 2024 for more cash to continue the works.

| Go to previous entry | Go to next entry | Go back to the archive index | Go back to the latest entries |